Your Field-Proven Partner for a Cleaner Future

Across North America, we are helping our customers and communities protect and renew our water and soil.

Exceeding Your Expectations

At APG, our mission is clear: To provide innovative environmental solutions to help customers and communities manage their residuals and wastewater for a cleaner future. We approach each of our customers with fresh eyes to develop customized, unique solutions.

APG exists to solve the critical residuals issues facing our customers, both large and small. Our unique approach is not only what differentiates us, but also what makes us successful. We provide a broad range of services and solutions including mechanical dewatering, both in mobile and fixed facility applications, dredging, lagoon cleaning, digester cleaning, tank cleaning, solids transportation and solids disposal, whether for landfill or for beneficial reuse.

Our Solutions

Dredging

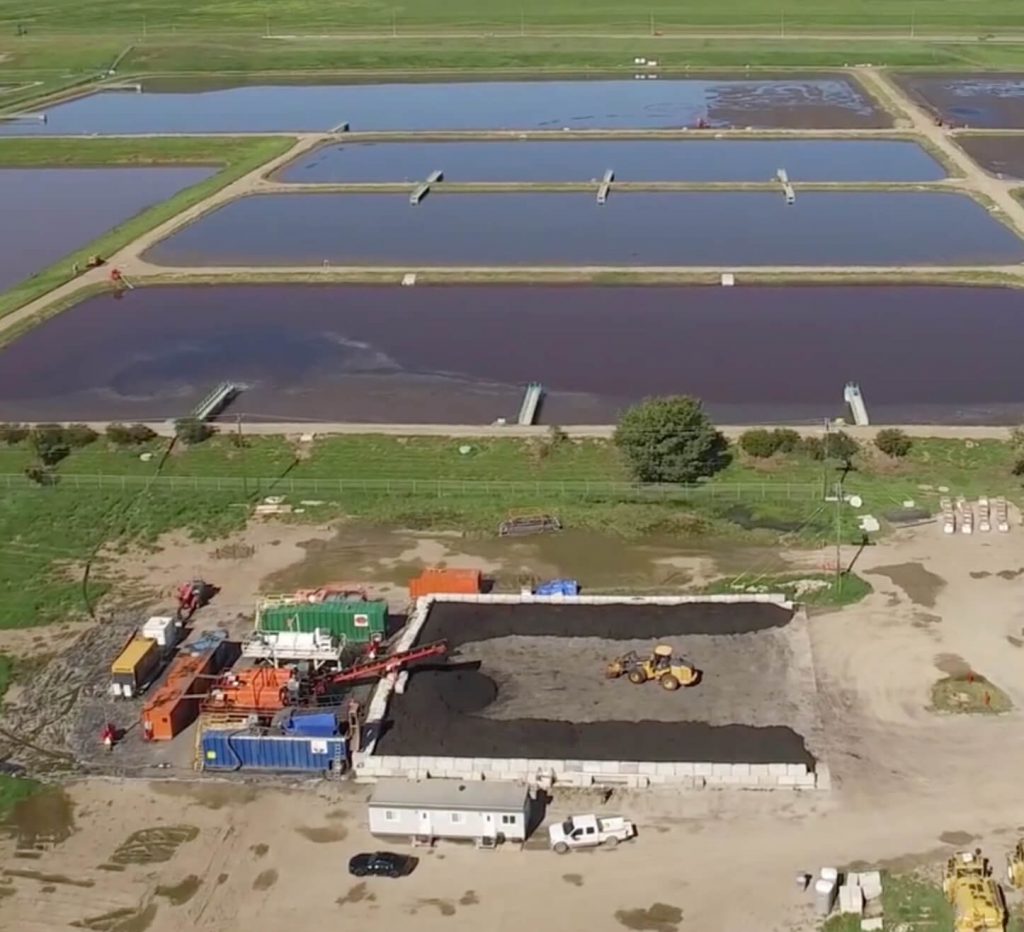

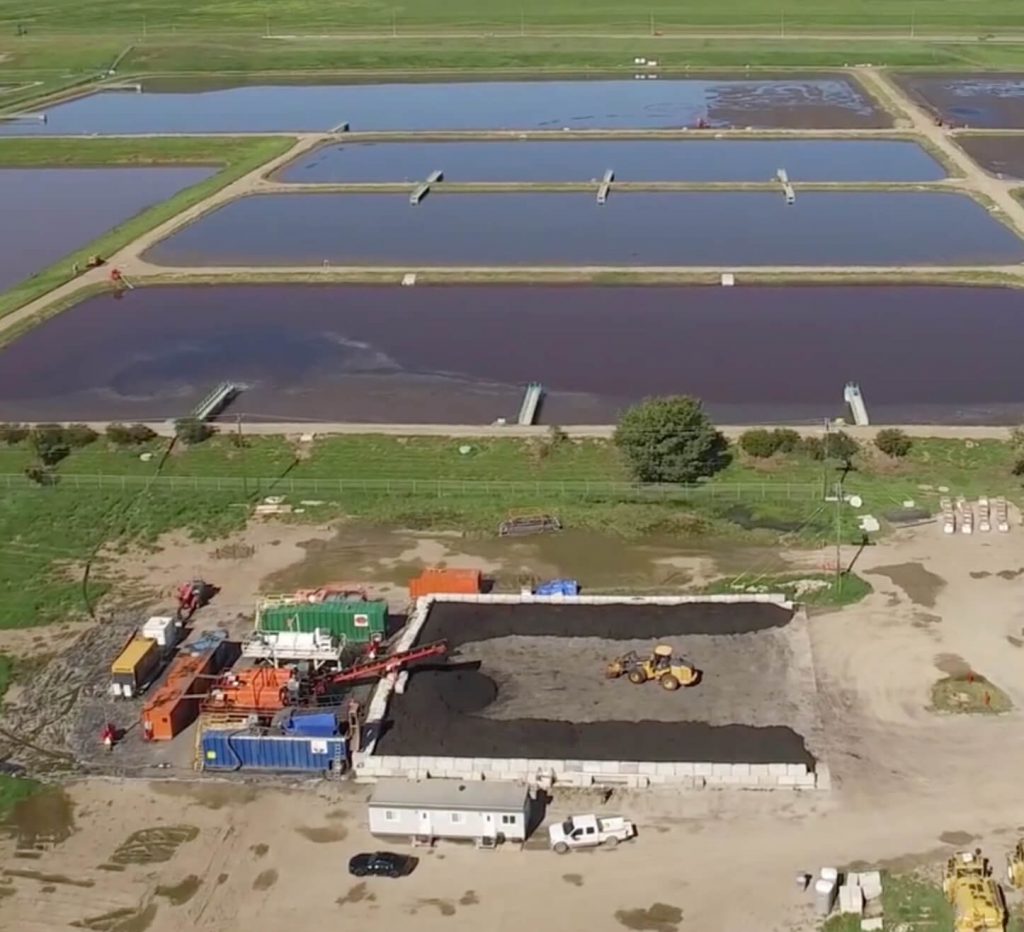

Our customers face many constraints, be it time, resources or capacity. Given our field proven expertise, our team of experts offers the critical support you need with the right dredging solution that alleviates your budget pressures and meets – or beats – your deadline. We’re committed to designing a custom solution that ensures regulatory compliance while minimizing impact on your operations and the environment.

The majority of our dredging operations are performed using auger dredges, transporting the slurry through a pipeline to shore. Our current fleet of dredges vary in size and capacities including a variety of cutter head styles for different slurry compositions allowing us to meet the demands of nearly any size project.

Dewatering

APG uses state-of-the-art Horizontal Decanter Centrifuge for dewatering along with other solid separation technologies, tailored to the project. The Centrifuge method produces dryer cake, with higher throughput and cleaner operations than other continuous process dewatering equipment.

All of APG’s centrifuges are mobile and have a turnkey plug-and-play operation ready to go within a few days. The quick set up and teardown allows for flexibility and the ability to handle small and large projects easily.

Lagoon Cleaning

Sludge builds up over time and degrades the performance of most lagoons, eventually pushing the effluent out of compliance on suspended solids or turbidity. APG’s specialized high volume dredges remove the solids content (slurry) from the bottom of the lagoon with no draining required.

APG’s method allows for the lagoon, pond, basin or lake to remain in active service throughout the cleaning process, whether it is a primary, secondary, activated or settling sludge. This is particularly important for certain industries that rely heavily on their lagoons including pulp and paper, wastewater treatment plants and oil and gas. APG carefully and expertly cleans lined lagoons without causing damage to the liner, regardless of whether it is man-made or earthen.

Digester Cleaning

Digester Cleaning

APG uses advanced technology to safety and efficiently clean all types of digesters. Their advanced pumping systems, screening equipment, and operation knowledge means they are the experts business turn to for digester cleaning.

All of APG’s operations personnel who work on digester projects are trained in confined space entry and rescue as well as any other safety training required, complying with all jurisdictions’ health and safety policies regarding confined space entry. Air quality is continuously monitored using air monitoring equipment, and emergency rescue equipment (e.g. SCBA) is on site should it be required. APG’s equipment is Hazardous Location Rated, suitable for this environment.

Our Solutions

Dredging

Our customers face many constraints, be it time, resources or capacity. Given our field proven expertise, our team of experts offers the critical support you need with the right dredging solution that alleviates your budget pressures and meets – or beats – your deadline. We’re committed to designing a custom solution that ensures regulatory compliance while minimizing impact on your operations and the environment.

The majority of our dredging operations are performed using auger dredges, transporting the slurry through a pipeline to shore. Our current fleet of dredges vary in size and capacities including a variety of cutter head styles for different slurry compositions allowing us to meet the demands of nearly any size project.

Dewatering

APG uses state-of-the-art Horizontal Decanter Centrifuge for dewatering along with other solid separation technologies, tailored to the project. The Centrifuge method produces dryer cake, with higher throughput and cleaner operations than other continuous process dewatering equipment.

All of APG’s centrifuges are mobile and have a turnkey plug-and-play operation ready to go within a few days. The quick set up and teardown allows for flexibility and the ability to handle small and large projects easily.

Lagoon Cleaning

Sludge builds up over time and degrades the performance of most lagoons, eventually pushing the effluent out of compliance on suspended solids or turbidity. APG’s specialized high volume dredges remove the solids content (slurry) from the bottom of the lagoon with no draining required.

APG’s method allows for the lagoon, pond, basin or lake to remain in active service throughout the cleaning process, whether it is a primary, secondary, activated or settling sludge. This is particularly important for certain industries that rely heavily on their lagoons including pulp and paper, wastewater treatment plants and oil and gas. APG carefully and expertly cleans lined lagoons without causing damage to the liner, regardless of whether it is man-made or earthen.

Digester Cleaning

APG uses advanced technology to safety and efficiently clean all types of digesters. Their advanced pumping systems, screening equipment, and operation knowledge means they are the experts business turn to for digester cleaning.

All of APG’s operations personnel who work on digester projects are trained in confined space entry and rescue as well as any other safety training required, complying with all jurisdictions’ health and safety policies regarding confined space entry. Air quality is continuously monitored using air monitoring equipment, and emergency rescue equipment (e.g. SCBA) is on site should it be required. APG’s equipment is Hazardous Location Rated, suitable for this environment.

Who We Serve

Municipal & Governmental

Pulp & Paper

Industrial Customers

Petrochemical

Major Projects

Contact

American Process Group (Canada) Ltd.

946 Boulder Blvd.

Stony Plain, Alberta

T7Z 0E6 Canada

Toll free: 866-960-1480

Phone: 780-963-1484

Fax: 780-968-1482

American Process Group Ltd.

1201 Pacific Avenue

6th Floor

Tacoma, Washington

98402 USA

Phone: 503-623-9373

Fax: 503-623-9374

780-221-5454